The camouflaging method selected is often based on available supplies,

expertise, and the experience of the practitioner. Other aspects depend on selecting

a substrate similar to the artifact's texture, color, pattern and design. Concern

for the durability and the magnet placement depends on the situation. In

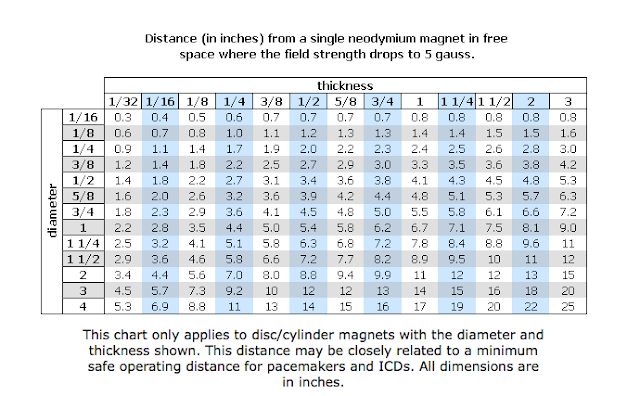

particular, the magnet's tolerance for being handled multiple times. Also, concern for its proximity to the visitor, especially in the case of patrons who might be susceptible to a magnet's effect (pacemaker wearers, for example).

Useful Tools:

If you must trim any material after it has been attached to the magnet, the

use of metal tools like standard metal scissors can be frustrating because your tool and magnet are attracted to each other. Luckily tools made of zirconia

(Zr, atomic number 40), like knives, are perfect and will not be attracted to a magnet. These

knifes are very sharp and brittle, so great care is needed to prevent them from breaking.

|

| Useful non-metallic tools that won't be attracted to a magnet |

Below is a list of various options for camouflaging a magnet:

A) PAINT

A layer of paint can be a quick camouflaging method, but it also brings challenges. One, is creation of an uneven application (it can be difficult to apply an even

coat on the plated surface of a magnet). Another, is protecting

the applied surface. An added protective coating is useful to aid in reducing

the potential of chipping. Another option is to "rough" the surface slightly, allowing for a

better grip of the paint to the magnet surface.

The painted surface on a magnet will become chipped or marred

when opposing sides are quickly snapped together. This often occurs when magnets

are removed and stored, or are placed near one another during preparation when

ferromagnetic materials are not present. To minimize this problem, ensure that

all of the magnets for one project are stored with the poles in the same

direction, so that the fragile painted layers repel each other.

This might not be a choice for magnets that are used

regularly. However, it can be an easy and quick method for short term needs. To do this, place them on inexpensive plumber’s tape

behind silicone Mylar, scrap steel, or a metal filling-system. (see the image below).

|

These block magnets are spaced far

enough apart to discourage them from

snapping together quickly. |

B. DIGITAL PRINT

An excellent camouflage technique is to use a digital image

to duplicate the surface that the magnet covers. Larger flexible magnets

are ideal for securing thin artifacts. Several conservators have published the technique, but on-line you can go to the Asian Art Museum's blog (http://www.asianart.org/exhibitions_index/batik-mounts) to read about it.

A digital print

can also be added to the outer surface of any rare-earth magnet (see photo below).

|

Camouflaging is created using a long flexible magnet that

is covered with a 1:1 image of the artifact it will secure.

|

Another approach to disguise the magnet is to apply materials that are the same, or with

similar texture, as the artifact that is being supported .

The materials are disguised by the color, texture or images in the local area

that is being covered, or even the actual embellishment itself (see the decorative element section below). Examples of materials that have been used include Japanese paper, mat board (http://www.conservation-wiki.com/w/index.php?title=Magnet_Mounts), Nomex, fabric (http://spicerart.com/2014/12/17/hunzinger-chair-re-tufted-with-magnets), Tyvek, felt, leather, artificial rawhide, and ultra suede.

When fabric is used, using a sufficiently tight

weave-structure to withstand the strength of the magnet is recommended. If the

weave-structure is too loose, then the fabric weakens prematurely.

|

|

Creating tufting on a chair seat using magnets. These magnets

will be covered with the same red show-cover fabric, creating a

camouflaging of the magnets.

|

D. DECORATIVE ELEMENT

Conservators have cited the magnet itself as the decorative

element and hence requires placement above the artifact. The decorative element in this case aids in determining the

size and strength of the magnet. If the magnet is replacing a missing element,

then the size is predetermined. But the grade can be adjusted to better match

the magnetic system.

When a magnet is securing the element to the artifact the

magnet needs to have the strength for support. The element can be a range of

sizes and shapes, large; and flat or small footprint and tall. A magnet must be selected that will secure the element, while also not damaging the artifact below.

|

| Decorative element secured to a costume using a magnet. |

E. Embedding

A successful method of placing rare earth magnets within materials is embedding them properly. Keeping the magnets surrounded by

materials aids in their longevity, by lessening the risk of demagnetization from both

shock and heat. These embedded magnets or ferromagnetic materials can be placed

on top or within an artifact, as well as used as a point fastener, or as

continuous pressure on the artifact.

Any three-dimensional artifact can be easily mounted and supported. The magnet or ferromagnetic material can be embedded and hidden inside. In addition, many of these systems can be reused. The wide selection of materials used are Ethafoam, pillows with batting and a baseboard, materials that are easily carved, and rigid or simple acid-free board. Read more about creating mounts here:

|

|

Ferromagnetic material attached

to an acid-free board inserted

into the base of a wooden box.

|

The shape of the magnet, whether using a disc or a block, does

not affect many of the methods described above. The only exception is cutting a

hole into mat board. Here having a block-shaped magnet could be simpler than

cutting a round hole, but a drill bit can be used.

At Spicer Art Conservation we are always interested to hear of magnet use success stories. In fact, Gwen Spicer, owner and principal conservator of SAC is busy writing a book about the use of magnets in conservation. The book features examples of successful magnet use by conservators. If you have a story or project you are particularly proud of, and would like to possibly be included with other successful magnet using conservators in the book, please share your own experience of covering and camouflaging magnets. We want to hear!

___________________________

Gwen Spicer is a conservator in private practice. Spicer Art Conservation specializes in the conservation of textiles, objects, and works of art on paper. Ms. Spicer is known for her innovative treatments and mounts using magnets.

Learn more about magnets and their many uses in the new publications Magnetic Mounting Systems for Museums and Cultural Institutions. Available for purchase at www.spicerart.com/magnetbook.

To contact Gwen, visit her website: www.spicerart.com or send her an email: gwen@spicerart.com.